Commercial driving accidents cost the trucking industry over $87 billion annually, making safety protocols non-negotiable for fleet operators and drivers alike.

At floridanewdriver.com, we’ve compiled proven commercial driving safety tips that reduce accident rates by up to 40% when consistently applied. These strategies protect both drivers and other road users while minimizing costly incidents.

Pre-Trip Safety Inspection Fundamentals

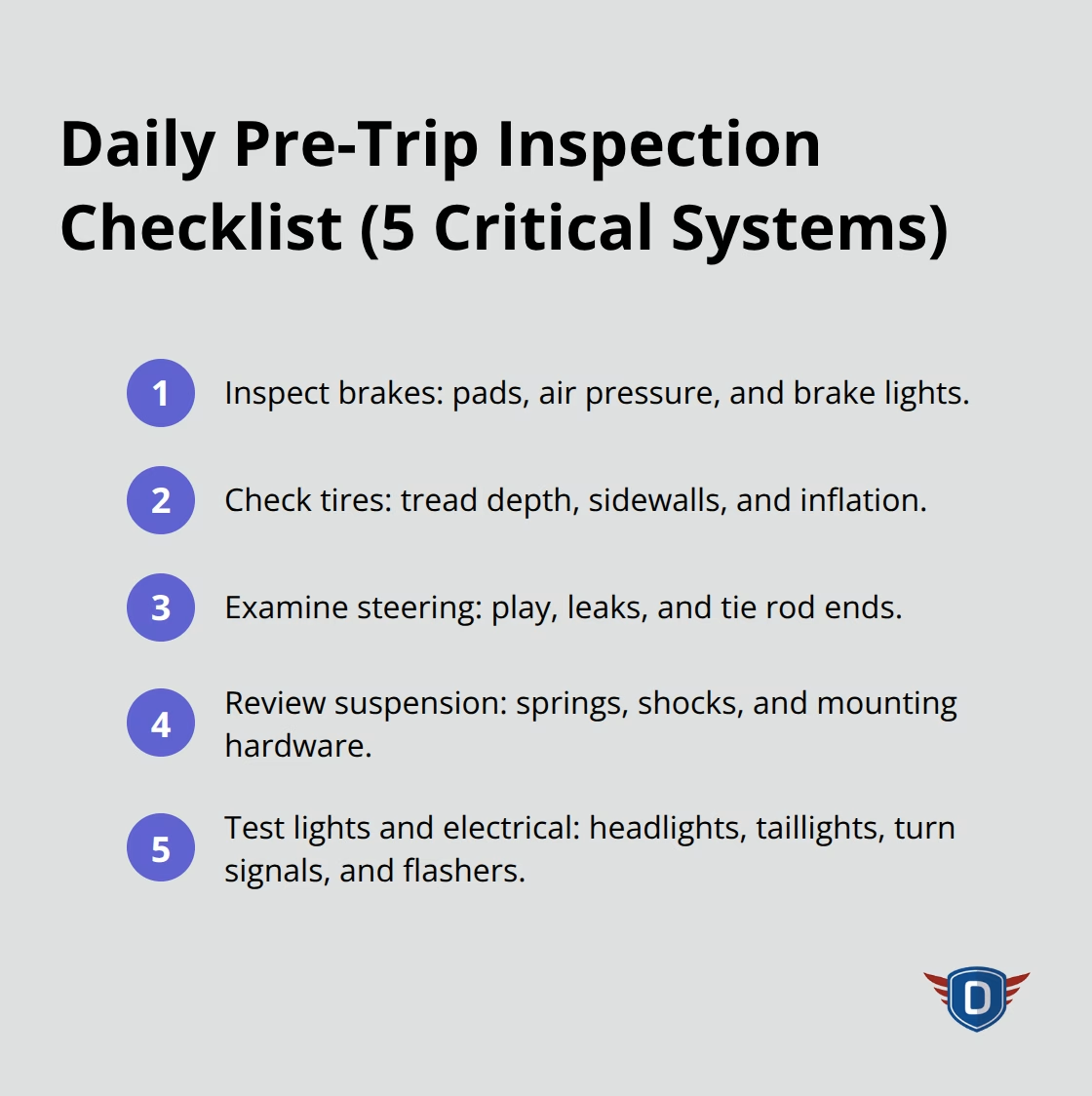

Pre-trip inspections prevent 85% of mechanical failures that lead to commercial vehicle accidents, according to Federal Motor Carrier Safety Administration data. Smart drivers focus on five critical systems during their daily inspection: brakes, tires, lights, steering, and suspension components.

Critical Vehicle Components to Check Daily

Brake systems demand your immediate attention during every inspection. Check brake pads for wear indicators, test air pressure systems, and verify all brake lights function properly. Tire inspections must include tread depth measurements (use the penny test), sidewall damage assessment, and proper inflation levels. Steering components require checks for excessive play, fluid leaks, and worn tie rod ends that could cause sudden control loss.

Suspension systems need visual inspection for cracked springs, worn shock absorbers, and loose mounting hardware. Lights and electrical systems require testing of all headlights, taillights, turn signals, and hazard flashers before departure.

Documentation Requirements and Legal Compliance

Federal regulations mandate written inspection reports for every commercial vehicle before operation. Driver Vehicle Inspection Reports must document all defects found and corrective actions taken. Electronic Logging Device integration now streamlines this process, automatically recording driving time and linking inspection completion times to Hours of Service records.

Drivers face fines up to $1,000 for incomplete or falsified inspection reports. Proper documentation protects both drivers and fleet operators from liability issues during DOT audits and accident investigations.

Technology Tools for Enhanced Inspection Efficiency

Modern inspection technology transforms routine checks into data-driven safety protocols. Wireless tire pressure monitoring systems alert drivers to dangerous pressure drops before blowouts occur. Digital brake stroke indicators provide precise measurements that paper checklists cannot match.

Advanced fleet management platforms like Samsara and Geotab integrate inspection data with vehicle performance metrics, predicting maintenance needs before breakdowns happen. These systems cost between $200-500 per vehicle monthly but reduce roadside breakdowns by 40% and lower insurance premiums through improved safety scores.

Mobile inspection apps photograph defects, generate instant reports, and alert maintenance teams in real-time. These digital tools reduce paperwork errors by 60% and speed up the inspection process from 45 minutes to under 20 minutes per vehicle. Once you complete your pre-trip inspection, the real challenge begins with safe operation on public roads.

On-Road Safety Techniques for Commercial Drivers

Commercial drivers face unique challenges that passenger vehicle operators never encounter. Large trucks require 40% longer stopping distances than regular cars, and the average 80,000-pound loaded truck needs up to 525 feet to stop completely at highway speeds according to Federal Motor Carrier Safety Administration studies. This physics reality demands aggressive defensive driving tactics that go far beyond standard passenger car techniques.

Defensive Driving Strategies for Large Vehicles

Professional drivers must scan the road 15 seconds ahead continuously and check mirrors every 8-10 seconds to monitor blind spots and traffic patterns. The University of Michigan Transportation Institute found that 70 percent of crashes involving commercial vehicles result from passenger car driver errors, making predictive driving skills essential for commercial operators.

Maintain lane position aggressively, signal turns and lane changes 200 feet in advance, and avoid sudden movements that confuse other drivers. Speed management becomes critical on grades where loaded trucks can lose momentum rapidly or gain dangerous speed on descents. Professional drivers anticipate traffic flow changes and position their vehicles to avoid emergency maneuvers.

Managing Blind Spots and Safe Following Distances

Large trucks create blind spots extending 20 feet in front, 30 feet behind, and two full lanes on the right side. Check these zones every 10 seconds using mirrors and avoid lingering in other vehicles’ blind spots. Maintain following distances of 1 second per 10 feet of vehicle length at speeds above 40 mph (which translates to 7-8 seconds for a standard 70-foot truck-trailer combination).

Weather conditions demand increased spacing: wet roads require 10-second gaps, while icy conditions need 15-20 second intervals to prevent jackknife situations. Professional drivers adjust their following distance based on load weight, road conditions, and traffic density to maintain control during emergency stops.

Weather-Related Driving Adjustments and Risk Management

Reduce speed by 10 mph in light rain and 20 mph during heavy precipitation or snow conditions. Black ice formation occurs when temperatures drop below 32 degrees Fahrenheit, particularly on bridges and overpasses that freeze first. High crosswinds exceeding 30 mph can destabilize empty trailers, requiring immediate speed reduction and potential route changes to avoid elevated roadways.

Professional drivers monitor weather radar continuously and plan alternate routes when severe weather threatens planned corridors. Wind advisories become particularly dangerous for high-profile vehicles, and smart drivers park their rigs rather than risk rollover accidents during extreme weather events.

These on-road safety techniques work best when drivers maintain peak physical and mental condition throughout their shifts.

Driver Health and Fatigue Management

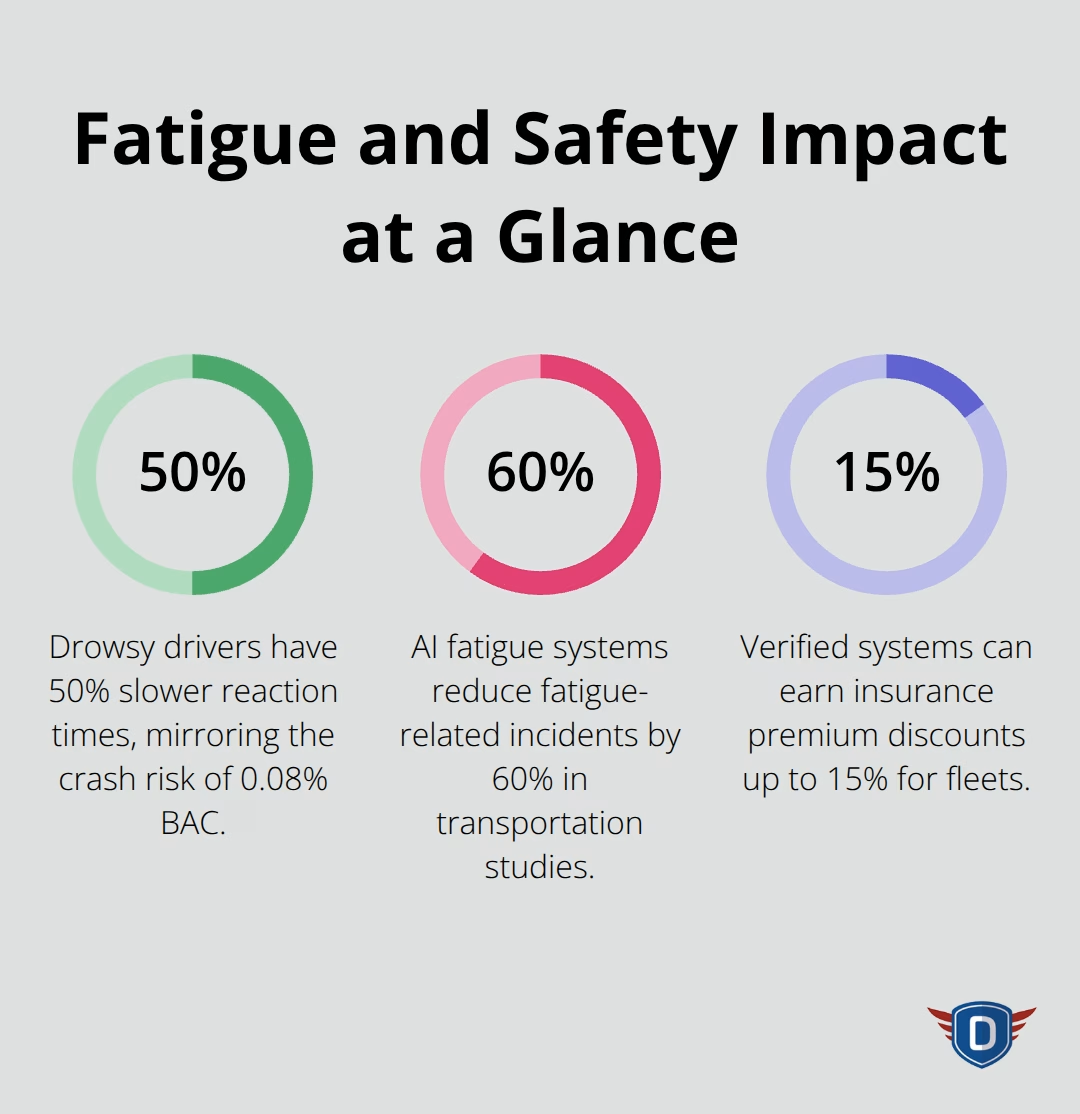

Driver fatigue causes significant commercial vehicle crashes according to Federal Motor Carrier Safety Administration data, killing over 4,000 people annually. The agency’s Hours of Service regulations limit drivers to 11 hours behind the wheel after 10 consecutive hours off duty, with mandatory 30-minute breaks after 8 cumulative hours on the road. These rules exist because drowsy drivers show 50% slower reaction times and create the same crash risk as drivers with a blood alcohol level of 0.08%. Professional drivers who violate HOS regulations face fines up to $2,750 per violation, while carriers can be penalized $15,400 for each offense.

Physical Warning Signs That Demand Immediate Action

Your body sends clear distress signals before fatigue becomes deadly. Microsleep episodes last 1-4 seconds and occur when drivers blink for extended periods or stare blankly ahead without processing visual information. Head nods, frequent yawns, and difficulty maintaining lane position indicate dangerous fatigue levels that require immediate rest. Professional drivers must recognize these symptoms and pull over within 15 minutes of onset, as continued operation increases crash risk by 800%. The National Sleep Foundation found that 20 hours without sleep creates the same impairment as legal intoxication.

Mental Health Strategies for Long-Haul Success

Commercial drivers face unique mental health challenges through isolation, irregular schedules, and constant pressure. Drivers who maintain regular sleep schedules at home reduce fatigue-related incidents by 35% compared to those with erratic rest patterns. Exercise programs targeting drivers show remarkable results: 30 minutes of walking or stretching every 4 hours improves alertness for up to 6 hours afterward. Proper nutrition prevents energy crashes that lead to microsleep episodes, with protein-rich snacks maintaining stable blood sugar levels better than caffeine or sugar-heavy alternatives.

Technology Solutions for Fatigue Detection

Modern fatigue management systems use artificial intelligence to monitor driver behavior and issue alerts before crashes occur. Eye-tracking cameras detect drooping eyelids, while steering pattern analysis identifies the subtle lane drift that precedes fatigue-related accidents.

Final Thoughts

These commercial driving safety tips create measurable results when drivers apply them consistently. Drivers who perform daily pre-trip inspections, maintain proper following distances, and manage fatigue effectively reduce their accident risk by 40% compared to those who skip safety protocols. The financial benefits extend beyond accident prevention: fleets that implement comprehensive safety programs see insurance premiums drop 15-25% annually while reducing vehicle downtime by 30%.

Professional development never stops in commercial driving. Technology advances rapidly, regulations change frequently, and new safety techniques emerge from ongoing research. Drivers who invest in continuous education through traffic school programs maintain better safety records and advance their careers faster than those who rely solely on experience.

We at floridanewdriver.com recommend that drivers establish monthly safety reviews where they assess their performance against these standards. Track your inspection completion times, monitor your habits with following distances, and document fatigue management strategies that work best for your schedule. Small improvements compound over time and transform good drivers into exceptional safety leaders who protect themselves and everyone who shares the road.